Olin Electric Motorsports

At Olin Electric Motorsports, I contribute to the design and fabrication of our Formula SAE electric racecar, focusing on the accumulator and electrical subsystems. Our team develops the entire vehicle in-house, from mechanical design to wiring integration, and I’ve specialized in creating mechanically sound, electrically safe systems that meet strict FSAE regulations. Over the past year, I’ve worked across several critical subsystems and will be leading the accumulator sub-team next season.

My Projects

Low Voltage Mounting

For the low-voltage subsystem, I designed a mounting system for the 12V 10Ah LiFePO₄ battery that powers the car’s electronics. The challenge was packaging the unit in a confined area between the firewall and the accumulator enclosure while meeting FSAE electrical and structural regulations.

A key design decision was selecting PETG as the material for the battery retainers. I chose PETG for its high thermal resistance and dimensional stability, which prevented warping or melting near heat-producing electrical components and under the Michigan sun. The design consists of three separate 3D-printed PETG brackets that secure the battery from all sides and are bolted to a welded steel base plate. The base plate incorporates water-cut mounting tabs, welded directly to the chassis to provide a strong and rigid foundation.

To verify the design, I performed hand calculations for shear and bearing stresses at the bolted joints and confirmed the results with Finite Element Analysis (FEA) under simulated 3g load conditions. The analysis ensured the PETG components acted primarily as isolators and locators while the steel base carried structural loads. The final design achieved full compliance with FSAE safety rules, maintained a high factor of safety, and was straightforward to manufacture and assemble within team constraints.

Master Switch Box

The master switch box controls the shutdown and power distribution system for both high- and low-voltage circuits. I inherited this project after previous iterations suffered from spatial interference and unreliable component fitment. Redesigning the box required balancing functional accessibility, wiring clearance, and regulatory spacing between high-voltage components.

The previous design used a vertical switch stack, but during packaging analysis I identified interference issues with the firewall and motor controller mounting brackets that limited both service access and cable routing. To resolve these conflicts, I redesigned the enclosure with a horizontal switch layout and shifted the entire box rearward, reducing its overall height and eliminating interference with surrounding components. This new orientation allowed the enclosure to fit cleanly beneath the firewall mounts and above the motor controller mounts, simplified cable management, and improved ergonomics for the driver during emergency shutdowns.

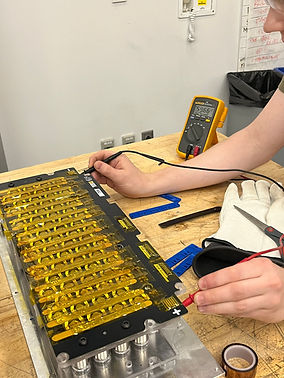

Battery Segments

The accumulator segments form the high-voltage energy storage system that powers the car’s drivetrain. Each segment houses multiple lithium-ion cells connected in series to produce approximately 60 volts per segment, supplying power to the Cascadia CM200 inverter. Because these assemblies operate at high voltage, every design decision had to balance electrical safety, mechanical integrity, and manufacturability.

During fabrication, I implemented CNC machining, epoxy bonding, spot welding, and lathe work to assemble the segments. These processes were chosen to achieve both precision and repeatability while maintaining electrical isolation between subcomponents. The cell tabs were spot welded for consistent electrical contact and reduced resistance variation, while the structural frame was bonded with high-strength epoxy to eliminate mechanical fasteners near live conductors and reduce vibration-induced fatigue.